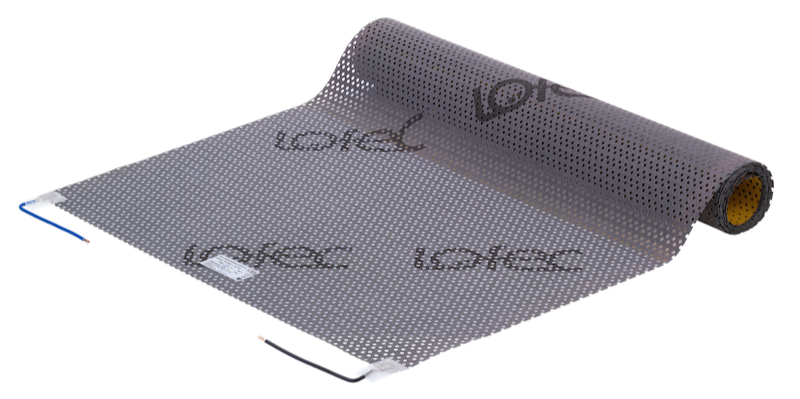

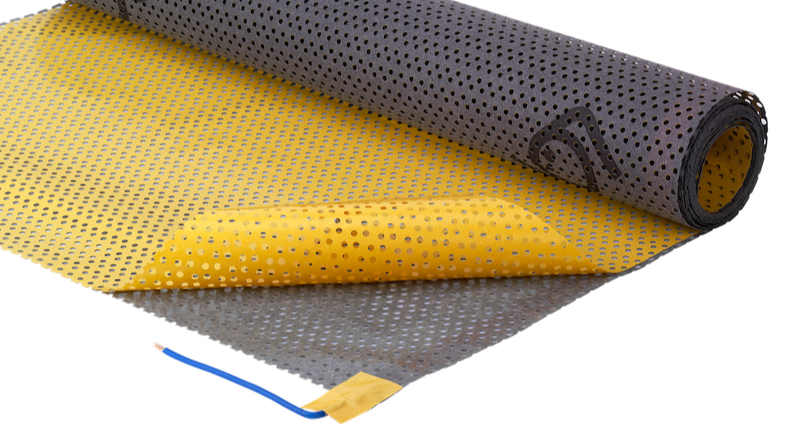

Easy Fix (self-stick)

The new generation of Lofec Heating Film

The demand on materials in construction is becoming ever higher and procurement is becoming more and more difficult. In addition, there is a shortage of skilled workers and ever shorter construction times. The construction industry will change a lot in the coming years. New ways, new building materials and new concepts will change the construction industry. Lofec GmbH is already following this path today and has the answers to the questions of tomorrow and the day after tomorrow. With the Lofec Easy Fix, like the name tell us, a new type of heating system will change the market. Processing has never been so easy. And all the advantages of Lofec Heating Film such as installation height, weight, safety have remained natural.

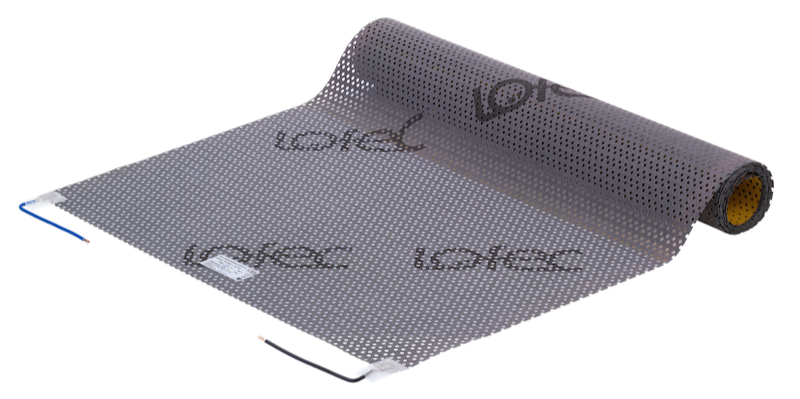

0,5 mm thin

0,5 mm thin 24V/32V/45V

24V/32V/45V 120g/m

120g/m Injury tolerant

Injury tolerant

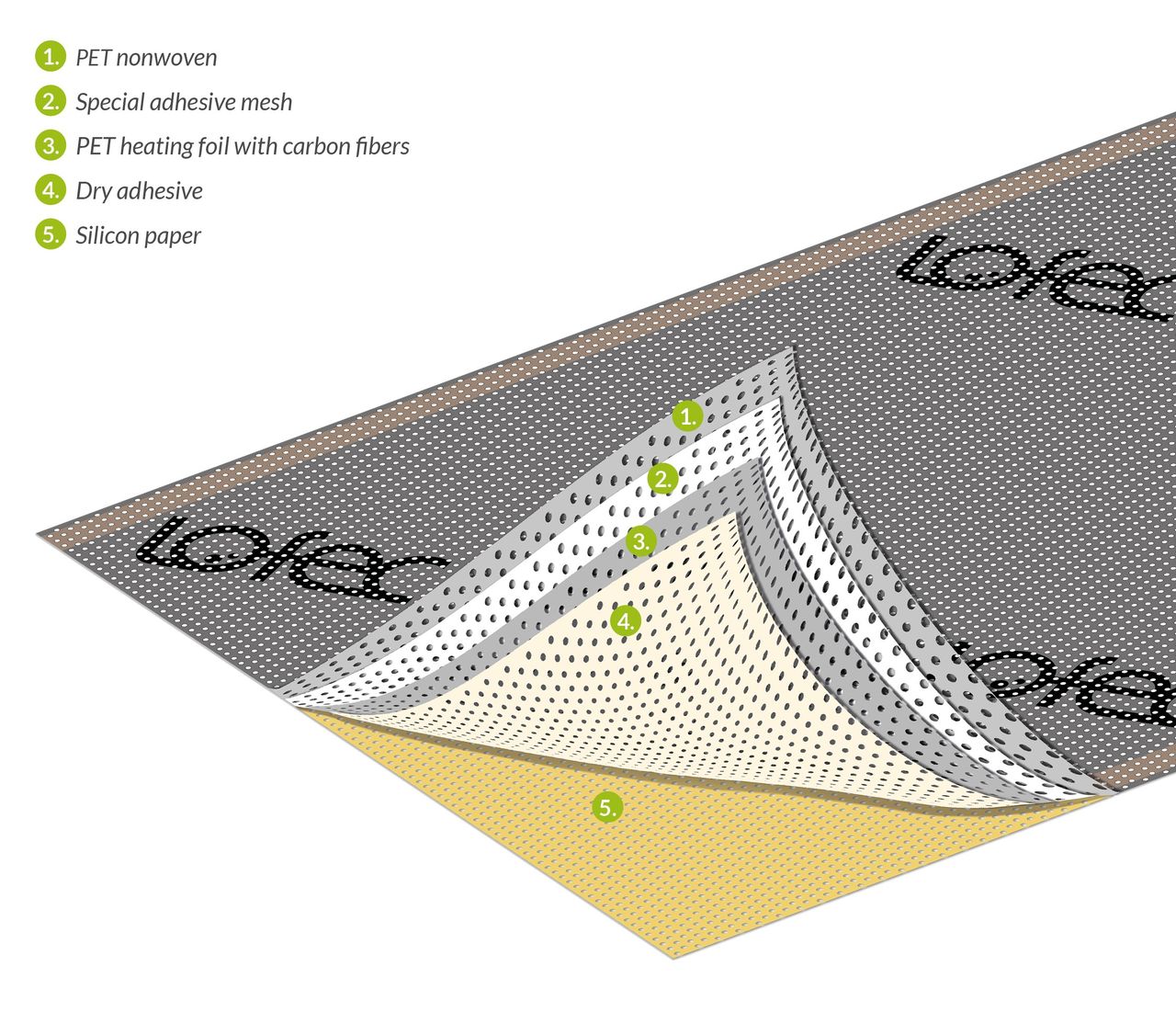

Into the Details

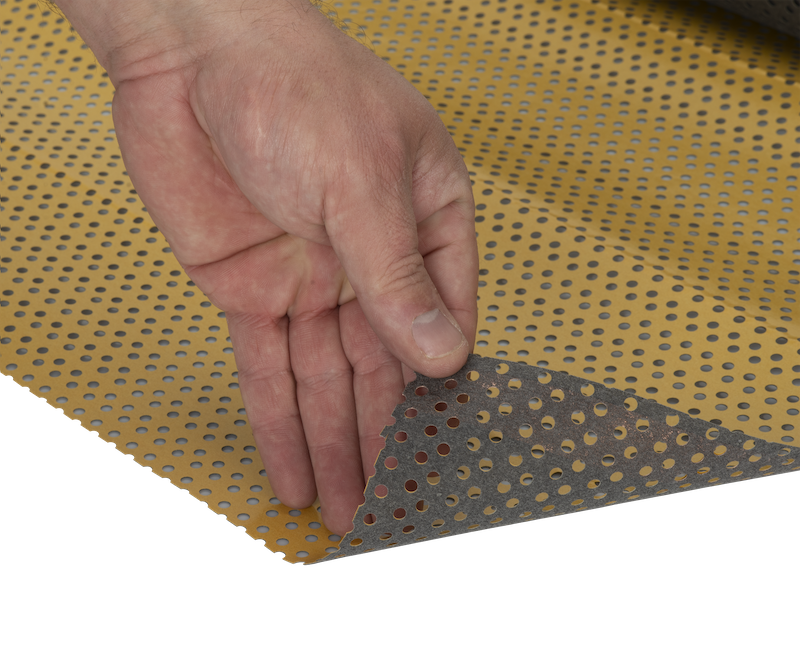

Easy Fix layer structure

Everyone is looking for solutions, we already have them!

The Lofec EasyFix was developed by Frank von der Weiden in order to be able to install the Lofec Heating Film even faster and more effectively in the „wall/ceiling/floor“ market.

With the new development and all the associated inspections and tests, it is now clear what potential this type of heating film has. Heating change quickly and easily, whether on wall, ceiling or floor. CO2-neutral heating of the future with the Lofec Easy Fix. The savings potential is huge! An underfloor heating for a house with 140m² you get installed in one day. Underfloor heating has never been so fast. And you also save money. Expensive and complex adhesives are no longer necessary, as the Easy Fix is already equipped with a special plasticizer-free adhesive. Primer, glue, done! And since there are no drying times, work can continue immediately. Extend and install cables, and shortly afterwards the balance can be done with a leveling and balancing compound.

The substrate must have sufficient stability and load-bearing capacity. It must be flat, solid, sufficiently old, dry, as well as free of sharp elevations and adhesion-reducing substances such as oil, wax, dust, release agents, efflorescence and sinter layers. In order to determine the maturity of the substrate and the measures necessary for the preparation of the substrate, the applicable standards and the recognized rules of technology must be observed and complied with. Inspect the substrate in accordance with applicable standards and leaflets and raise concerns if there are defects. Moisten the substrate. In case of oily residues, wipe the soil with a mild, diluted cleaner, then neutralize well with water. Do not use basic cleaners and do not grind.

Waste codes: AVV 20 03 01

Mixed municipal waste

Disposal